Winston Foodservice

The most precise commercial kitchen equipment.

Curious about us? We’ve been building commercial kitchen equipment for decades. Things have certainly changed through the years. But one thing remains constant: we understand the business and we get our customers.

Winston Industries came into being because of our partnership with a famous Colonel. We developed a fryer specifically to meet his restaurants’ needs.

Our founder, Winston Shelton, left a solid engineering career at General Electric in the late 1960s because of his entrepreneurial spirit and drive to create. He developed a whole new class of cooking and holding equipment.

We’re building upon this legacy because we believe in developing partnerships with customers. There is an entrepreneur in each of us. It’s the reason we’ve expanded our business – with innovation, new products, and geographical growth – to perpetuate our entrepreneurial spirit and provide the opportunity for others to do the same.

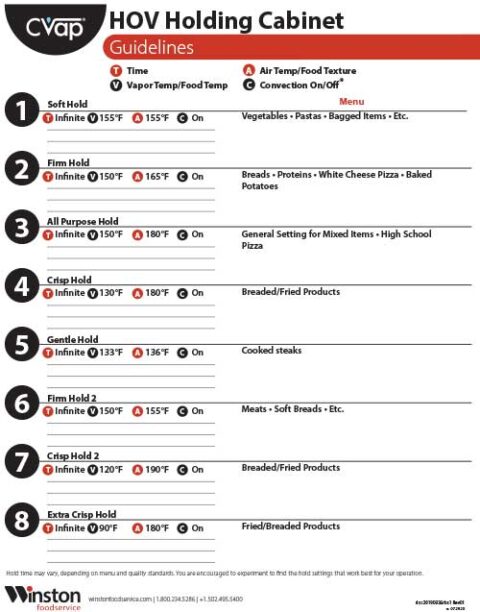

CVap® (Controlled Vapor Technology) rewrites the rules of food quality. What makes it different? Water vapor! All commercial kitchen equipment uses hot air to affect food. Some even use “humidity” to improve the amount of control they can claim. But only CVap technology uses heated water vapor to precisely control food temperature. Pair that with air heat to control texture, and you have an unbeatable combo (no, we didn’t say combi). CVap technology is available in Cook and Hold Ovens, Retherm Ovens, Holding Cabinets, and Hold and Serve Drawers. There’s a size and configuration to fit every commercial kitchen equipment need.

CVAP is revolutionizing professional kitchens. Increase product yield, improve consistency, shorten your tickets times, the list goes on. Retherm, Cook n Hold, Holding cabinets & drawers, there is a solution for you from Winston. All of which can be done outside your hood.

![]() Cook overnight

Cook overnight![]() Retherm

Retherm![]() Staging (our version of Souse Vide)

Staging (our version of Souse Vide)![]() Hot holding

Hot holding

Operators using Collectramatic Frying Equipment can expect a consistent, evenly-fried product every cook cycle, with little attendant labor. Foods are crisp on the outside, moist and delicious on the inside. Programmable microprocessor controls are easy to use, and store cook times and temperatures for up to eight products. The unique design and cold zone collector make all-day cooking possible with very little or no filtration. Flavor transfer is nearly eliminated and shortening life is dramatically extended.